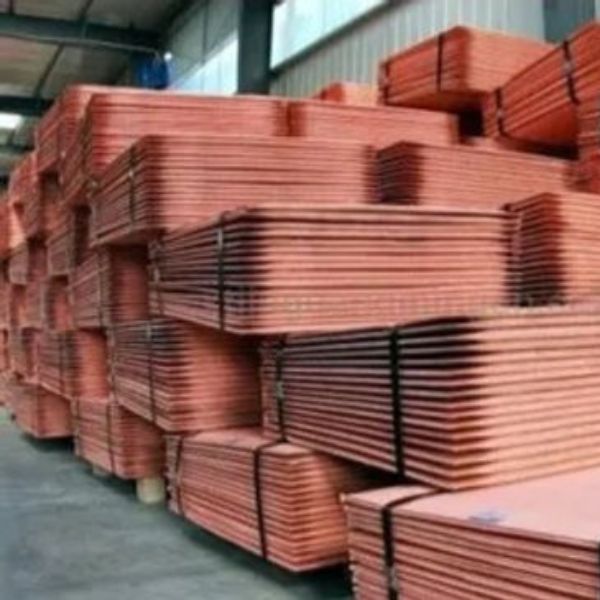

Copper Cathode – Scrap Metals 99.95%

Copper cathodes are used as a raw material feed for the production of high purity copper and copper alloy products. Copper has a purity of 99.95% or greater.

Copper cathodes are used as a raw material feed for the production of high purity copper and copper alloy products. It is therefore essential that, during shipping and transportation, they are not contaminated with any extraneous materials.

Chat Via WhatsAppProduct Details

Copper Cathode

Buy Copper Cathode, Individual cathode sheets are manufactured to different dimensions by different suppliers in the range of 0,5 m2 to 1 m2 and 3 to 20 mm thick, with or without ‘ears’.

Copper cathode is the primary raw material input for the production of copper rod for the wire and cable industry. Copper is also used in the production of brass, copper tube, copper sheet products, and found in over 450 alloys.

Copper Production from Ore to Finished Product

From its original home buried underground in a mine to its use in a finished product such as wire or pipe, copper passes through a number of stages. When it is recycled it can pass through some over and over again. Below is a quick description of the path.

1. Mining, Crushing

The beginning for all copper is to mine sulfide and oxide ores through digging or blasting and then crushing it to walnut-sized pieces.

2. Grinding

Crushed ore is ball or rod-milled in large, rotating, cylindrical machines until it becomes a powder usually containing less than 1 percent copper. Sulfide ores are moved to a concentrating stage, while oxide ores are routed to leaching tanks.

3. Concentrating

Minerals are concentrated into a slurry that is about 15% copper. Waste slag is removed. Water is recycled. Tailings (left-over earth) containing copper oxide are routed to leaching tanks or are returned to the surrounding terrain. Once copper has been concentrated it can be turned into pure copper cathode in two different ways: Leaching & electro winning or smelting and electrolytic refining.

4a. Leaching

Oxide ore and tailings are leached by a weak acid solution, producing a weak copper sulfate solution.

5a. Electro winning (SX/EW)

The copper-laden solution is treated and transferred to an electrolytic process tank. When electrically charged, pure copper ions migrate directly from the solution to starter cathodes made from pure copper foil. Precious metals can be extracted from the solution.

OR

4b. Smelting

Several stages of melting and purifying the copper content result, successively, in matte, blister and, finally, 99% pure copper. Recycled copper begins its journey to finding another use by being resmelted.

5b. Electrolytic Refining

Anodes cast from the nearly pure copper are immersed in an acid bath. Pure copper ions migrate electrolytically from the anodes to “starter sheets” made from pure copper foil where they deposit and build up into a 300-pound cathode. Gold, silver and platinum may be recovered from the used bath.

6. Pure Copper Cathodes

Cathodes of 99.9% purity may be shipped as melting stock to mills or foundries. Cathodes may also be cast into wire rod, billets, cakes or ingots, generally, as pure copper or alloyed with other metals.

7. Cathode is converted into:

Wire Rod – Coiled rod about 1/2″ in diameter is drawn down by wire mills to make pure copper wire of all gages.

Billet – 30′ logs, about 8″ diameter, of pure copper are sawed into these shorter lengths which are extruded and then drawn as tube, rod and bar stock of many varied sizes and shapes. Rod stock may be used for forging.

Cake – Slabs of pure copper, generally about 8″ thick and up to 28′ long, may be hot- and cold-rolled to produce plate, sheet, strip and foil.

Ingot – Bricks of pure copper may be used by mills for alloying with other metals or used by foundries for casting.

Shipment / Storage / Risk factors

Bundles of cathode sheets of between 1 and 4 tonnes and held together by steel strapping are shipped unpackaged. Care should be exercised during handling to avoid straps breaking which cause the bundles to become unstable with potential separation and loss of some sheets.

Electrolytic copper cathodes are usually bought upon a weight basis, and are normally shipped unpacked, often bound together with metal bands. During handling of bundled cathodes, care should be taken that rough handling does not cause breakage of metal bands.

It is quite common for cathodes to have surface excrescences arising out of the process of manufacture, in the nature of small ‘pimples or warts’. Handling in the course of transit may result in these surface irregularities being broken down and the cathodes delivered with a smooth surface.

This may result in a difference between shipped and delivered weights. Cathodes are manufactured with ‘ears’ for hanging purposes and frequently these ‘ears’ are knocked off, resulting in further loss of weight. When over-stowed, care should be taken that other cargo does not cause deleterious contamination of the copper.

Copper Cathode for Sale

Copper cathode is a form of copper that has a purity of 99.95% or greater. To produce copper cathode from copper ore, the impurities must be removed through two processes: smelting and electrorefining. The end result is nearly pure copper with unmatched conductive properties, perfect for use in electrical wiring. We also sell Tanzanite contact us for more information.

Product Specifications:

GRADE “A” MIN.CU – PURITY 99.97% -99.99%

Dimension – 914mm x 914mm x 12mm (LME Standard)

Weight of each sheet: 125 +/- 2% kg

Net weight each pallet: 2.0 MT +/- 2%.

Net weight per container: 20.0 Metric Tons (Approximately ± 2%)

Buy Copper Cathode Online

Copper cathode is a highly refined form of copper, typically with a purity level of 99.99%. It is produced through electrolytic refining, where impure copper is dissolved in an electrolyte solution, and pure copper is deposited onto cathodes. These cathodes are harvested, washed, and melted to remove any remaining impurities, resulting in a high-purity copper product.

Physical and Chemical Properties

Purity: 99.99% Copper

Form: Rectangular plates, typically weighing between 50 to 80 kg each

Color: Reddish-brown

Density: 8.96 g/cm³

Conductivity: Excellent electrical and thermal conductivity

Production Process

The production of copper cathodes involves several steps:

Mining and Crushing: Copper ores are mined and crushed into fine particles.

Concentration: The ore is concentrated using froth flotation.

Smelting: The concentrated ore is smelted to produce copper matte.

Refining: The copper matte undergoes electrolytic refining. In this process, an electric current passes through an electrolyte solution, causing pure copper to deposit onto cathodes.

This process ensures that the final product, the copper cathode, is of extremely high purity and suitable for various industrial applications.

Applications

Electrical Industry:

Wiring and Cables: Due to its superior electrical conductivity, copper cathode is extensively used to manufacture electrical wiring and cables.

Electronic Components: Used in producing printed circuit boards (PCBs) and connectors.

Construction:

Plumbing and HVAC Systems: Copper’s durability and antimicrobial properties make it ideal for plumbing pipes and HVAC systems.

Roofing and Structural Applications: Utilized in roofing materials and structural components due to its resistance to corrosion and ability to withstand environmental conditions.

Manufacturing:

Machinery and Equipment: These produce industrial machinery and transportation equipment, where malleability and durability are beneficial.

Automotive Industry: Used in various automotive components, contributing to improved efficiency and longevity.

Renewable Energy:

Solar Panels and Wind Turbines: Integral in producing renewable energy systems, aiding the transition to sustainable energy sources.

Electric Vehicles (EVs): Essential for manufacturing components for electric vehicles, including batteries and electric motors.

Healthcare:

Medical Devices: These are used in medical equipment due to their excellent conductivity and biocompatibility.

Radiation Shielding: Provides effective radiation shielding in medical facilities.

Copper cathodes are fundamental in many industries due to their high purity, excellent conductivity, and versatile applications. They are critical in modern technology and infrastructure, driving advancements and supporting sustainability initiatives globally.

Which countries do we serve?

We have sold copper cathodes to millions of people and I can assure you with a SATISFACTION GUARANTEE, we ensure that every customer is satisfied. Buy Copper Cathode in Toronto, Ottawa, Winnipeg, Edmonton, Brampton, copper in Ontario, St. John’s, Windsor, Victoria, Regina, Fredericton, St. Catharines, Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Buy Copper Online Mississippi, Missouri, Montana, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Utah, Vermont, Virginia, Washington, West Virginia, Wisconsin, and Wyoming.

Order Copper in Singapore, New Zealand, United States, United Kingdom, Australia, Denmark, United Arab Emirates, Philippines, South Africa, Canada, Nepal, Malaysia, Belgium, Finland, Croatia, Hong Kong, Netherlands, Norway, Ireland, Switzerland, Bulgaria, Sweden, Portugal, Thailand, Germany, Greece, Romania, Ukraine, Buy Copper Cathode Online Czechia, Mexico, Indonesia, Italy, France, Colombia, Spain, Poland, Vietnam, Saudi Arabia, Brazil, Chile, Russia, South Korea, UK, USA, Qatar , Copper in Macao, San Marino, Norway, Iceland, Luxembourg, Estonia, Cyprus, Isle of Man, Kuwait, Moldova, Malta, Lithuania, Austria, Sweden, Latvia, Belarus, Serbia, Slovakia, Buy Copper Online Kosovo, Monaco, North Macedonia, Kazakhstan, Albania, Turkey, Andorra, China, Malaysia, India, Philippines, Israel, Taiwan, Iran, Pakistan, Cambodia, Bangladesh, Iraq, Sri Lanka, Mongolia, Lao, North Korea, UAE, Argentina, and Japan plus more.

Buy Copper Cathode in Albania, Liechtenstein, Armenia, Azerbaijan, Bosnia and Herzegovina, Montenegro, Czech Republic, Estonia, Russia, Finland, San Marino, Former Yugoslav Republic of Macedonia, Slovenia, and Buy Copper Online Hungary.